Wear Protected Piping Systems ,

Wear-proof protection for pipe bends

Hydraulic and pneumatic pipe systems often must withstand extremely harsh conditions. Conveying abrasive materials such as clinker, ash, sand or sinter dust subjects pipelines to acute levels of stress. Even thick-walled steel or cast-iron pipes often show significant signs of wear in an extremely short period of time. Pipe bends, where flow is subject to heavy turbulence, are particularly susceptible to wear, often achieving a service life of only 1/20th that of the associated straight pipe runs.

FEATURES & BENEFITS

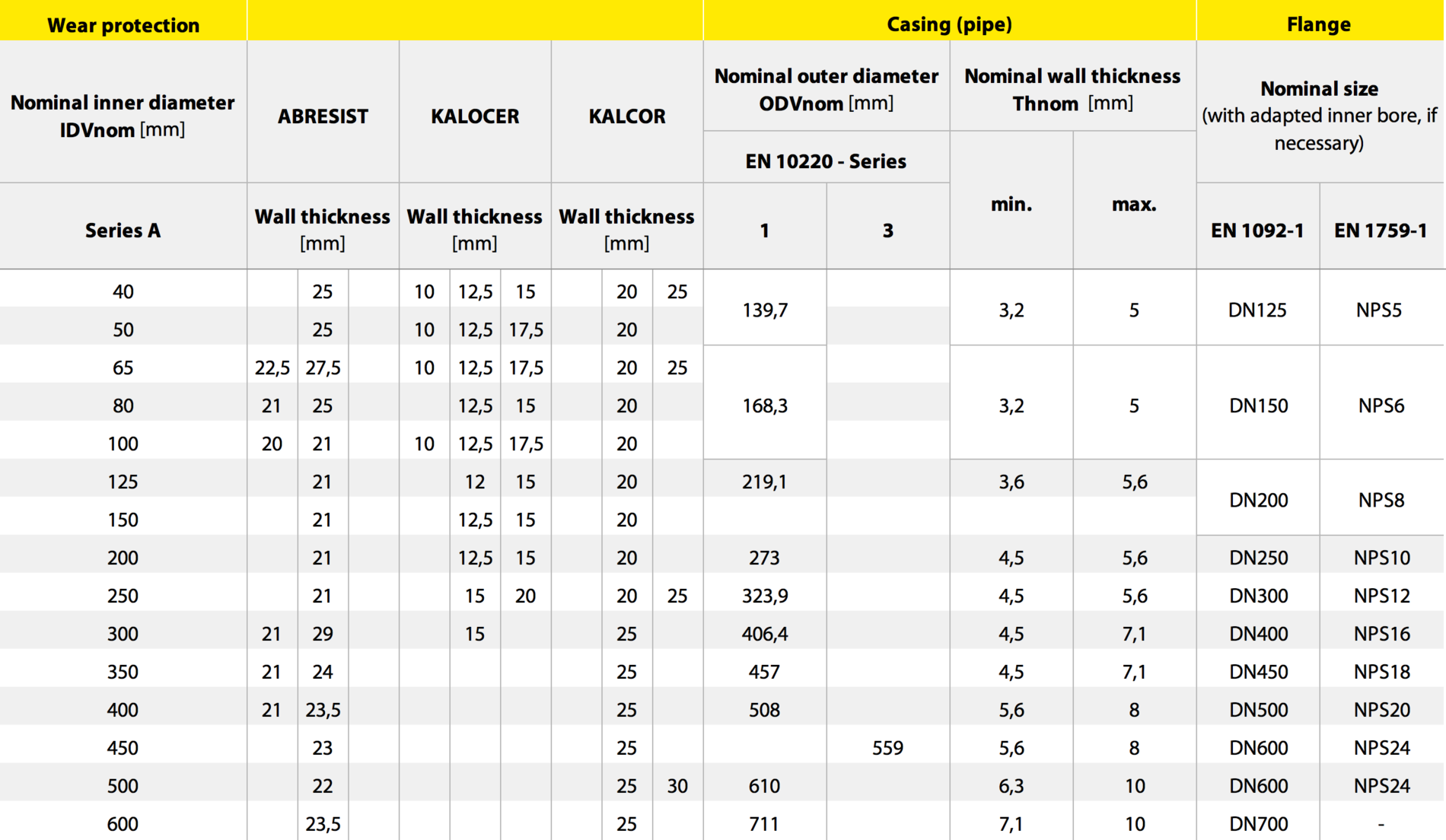

PRODUCT SPECIFICATIONS

TECHNICAL PROPERTIES

WEAR PROTECTED PIPING SYSTEMS – Standard according to DIN EN ISO

GALLERY

LITTERATURE DOWNLOADS

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.