KALIMPACT , Hard Composite Rubber

As a hard material composite formed with rubber, KALIMPACT is primarily used where high impact loading occurs in combination with heavy abrasion. The wear protection material is vulcanized in rubber.

Depending on the specific abrasion and impact resistance requirements, KALIMPACT comprises either fused cast basalt ABRESIST, oxide ceramics KALOCER or welded hard surfacing KALMETALL.

FEATURES & BENEFITS

The combination of a rubber base vulcanized on various materials, provides excellent wear resistance for multiple applications.

Depending on the application and the predominant type of impact, we may suggest our KALIMPACT solutions with rubber vulcanized on Kalocer Ceramics , Hard Kalmetall plates , Abresist Basalt plates… in various shapes and thicknesses ,

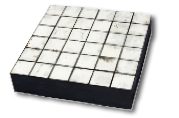

KALOCER in mosaic mats

PRODUCT SPECIFICATIONS

TECHNICAL PROPERTIES

MINERAL BASED WEAR-PROTECTION

The hardness values in brackets (HV Vickers) are for indication only

ABRESIST , KALOCER, KALCOR, KALCERAM ,KALCRET ,KALSICA, are trade names of KALENBORN KALPROTECT GmbH , Germany

GALLERY

LITTERATURE DOWNLOADS

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.